From the Bench: Flip & Save

Sometimes worn watch parts are too damaged to save, but some parts are designed in a way that gives them a second chance at life.

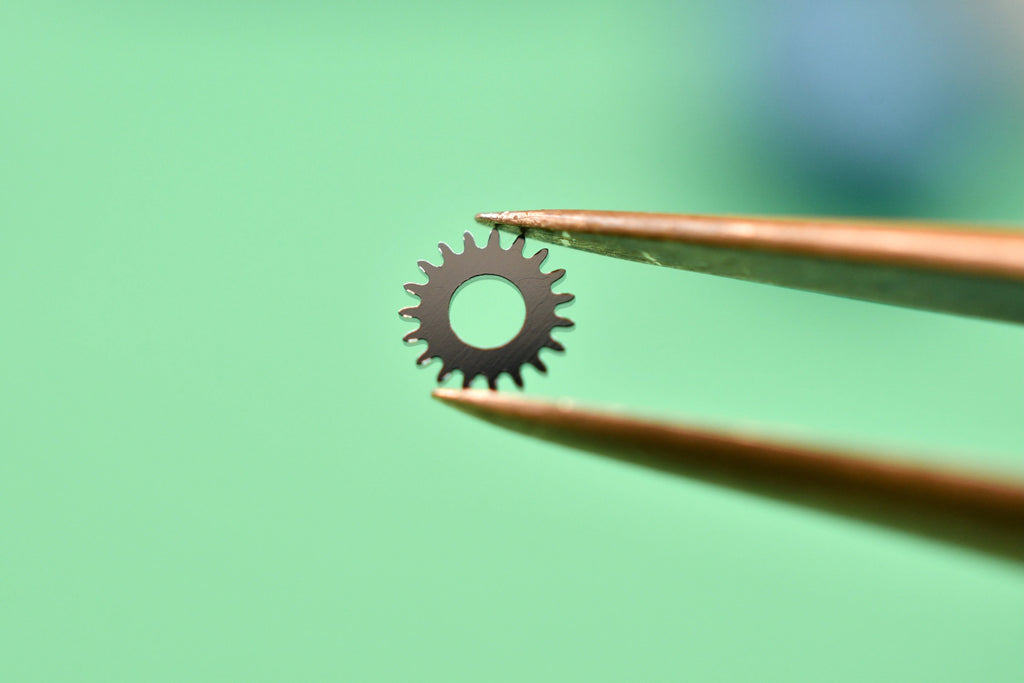

This is the crown wheel from a Soprod C125, the automatic GMT movement that you’ll find in our Sandford. On one edge of the teeth, you can see a slight “burr” where the metal has been extruded upwards during use.

Crown wheels are under a lot of stress whenever the watch is manually wound. It sits directly above the winding pinion, and is driven by the force of your fingers to power the winding mechanism. Your hands are significantly more powerful than any force the mainspring can muster, so this is an important area to check for wear.

Wheels are generally cut to turn on parallel planes, so the 90 degree offset, combined with the high torque of winding, causes these burrs to rise up over the course of use. It’s not uncommon or faulty, but if left unchecked the burrs can cause rough winding.

Luckily, because this is a symmetrical wheel, we don’t need to replace it yet!

Flipping the wheel over, you can see that the teeth are still in great shape. Since there’s no reason that this wheel has to be in one orientation or the other, we can just reinstall the wheel “upside down,” allowing the fresh sides of the teeth to engage with the winding pinion.

Reassembled after cleaning, the burrs are safely out of harm’s way, and the wheel is ready to take as much abuse as you can dish out—at least until the next service.

Think your watch might be ready for a tune up? Submit a Service Request form and we'll get your watch back into fighting form.