What’s a Full Service: Part 2, Epilame and Pre-Assembly

Once the movement is out of the ultrasonic cleaner, it goes through one additional treatment before actual assembly: epilame.

Epilame is a chemical that dramatically increases the surface tension on whatever it’s coating, allowing liquids to bead up, rather than spread around. This is extremely helpful for certain portions of the movement, like the escapement, which need grease to stay precisely in place. It also just generally helps with cleanliness.

Certain parts of the movement are not epilamed, like the balance and hairspring, because we want to leave them perfectly clean and untouched. Most of the geartrain’s wheels and pinions are also left un-epilamed, since they should never encounter grease or oil.

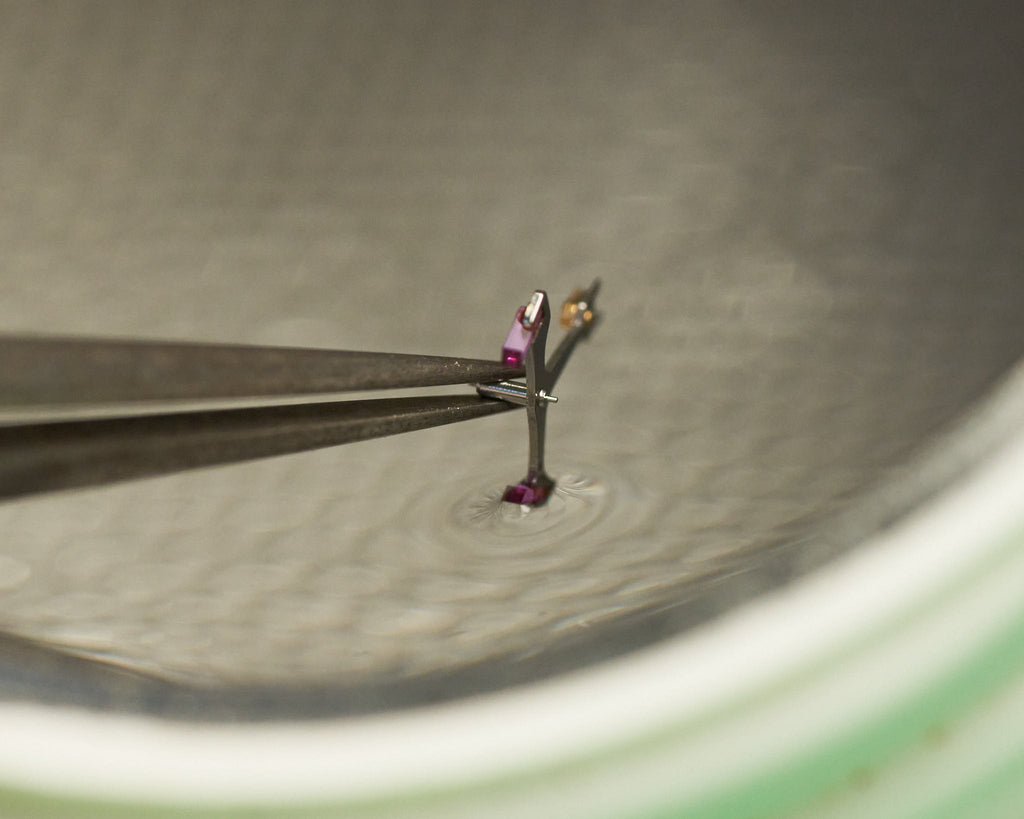

Pallet forks are the most delicate piece to epiliame, since we only want the surface treatment on the pallet jewels themselves. There is so little torque at the pallet that even the microscopic epilame coating could have a friction effect, so the pivots and notch of the fork are left dry, with just the tiny dipped individually into the solution.

Once dry, we’re almost ready to begin. Just two more steps!

Mainsprings don’t go in the ultrasonic cleaner because they have a teflon anti-friction coating that can get zinged off in the cleaning basket. They’re either manually cleaned with a tiny bit of watch paper, or ideally, replaced outright. Mainsprings are a bit like the water pump in a car engine—you don’t need to replace it while you have the timing belt off, but you might as well while you’re in there, because if it fails, the whole system goes down.

The last pre-assembly step is to lubricate the balance jewels. Modern shock-protected movements have jewel assemblies that come right out, which makes them simple to lubricate on the benchtop. A tiny drop of light oil is placed dead center on the cap jewel and the hole jewel is lowered perfectly on top of it. Oiling can be done manually or with an “automatic oiler” that pre-doses the oil drop. Frankly, it’s one of the more delicate processes in a service and could even earn its own blog post.

With all necessary parts epliamed and pre-lubricated, it’s time to put this thing together.

This is part 2 of a four part series on Oak & Oscar's full service. Read the related parts:

Thinking your watch is ready for a full service? Contact us to get started.